Select Language

Select Language

Empowering Value with Expertise, Shaping The Future Through Service

I. Pre-Sales Service System

1. Need Insight Mechanism

Industry expert team conducts on-site research of client application scenarios

Establishes a three-dimensional needs analysis model(functional requirements / environmental parameters / cost budget)

Delivers Product Development Evaluation Record Form and technical parameter comparison tables

2. Solution Recommendations

Visual comparison of core performance indicators (abrasion resistance / temperature resistance / compression set resistance, etc.)

Organizes industry experts to conduct finite element stress analysis, operating condition analysis, and core pain point analysis for products

Provides at least 3 Differentiated solutionsbased on client performance requirements

II. Customization Service Matrix

1. End-to-End Customization Management

Needs Confirmation

Solution Design

Prototype Validation

Small-Batch Product Testing

Large-Batch Product Testing

Mass Production Delivery

2.Technical Empowerment Advantages

10,000+ Custom Case Library Built Over 28 Over Of Industry Experience

Material Analysisi Supported By National-Level Accredited Laboratory

Professional Mateial Formulation Optimization,Technical Support,And Industry Insights From Domain Experts

Dedicated Service Code: Enables Full Lifecycle Traceability Management

Customized Case Library

Material analysis

Industry Experience

Exclusive Code

III. After-Sales Service Commitments

1. Quality Assurance System

Six-layer quality inspection standards(raw materials / mixing / vulcanization / dimensions / performance / appearance)

98.9% client repurchase rate validates our quality promise

2. Rapid Response Mechanism

8-hour inquiry response (including professional technical answers)

4-day express prototyping(in-house mold workshop and dedicated mold design/manufacturing team for rapid turnaround)²

7-14-day delivery cycle(supports green channels for urgent orders)

48-hour complaint response(provides investigation reports and clear resolution plans)

3. Value-Added Service Package

Free technical training (online + offline)

7×24-hour lifetime maintenance consultation

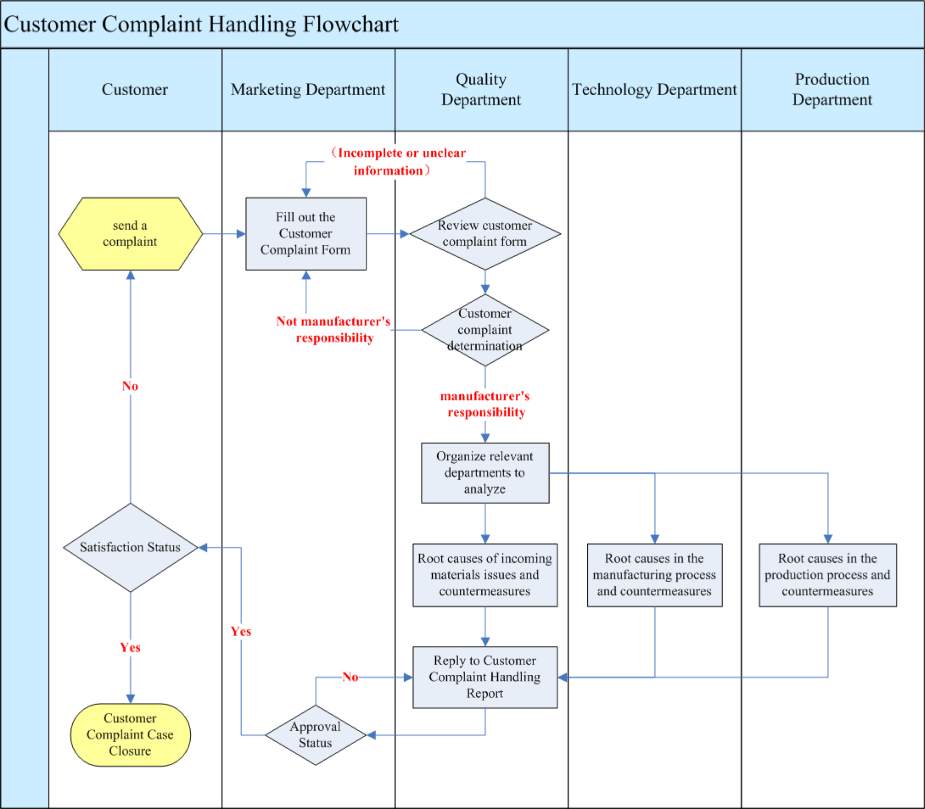

4. Complaint Handling Flowchart

IV. Client Success Stories

Client Case 1: German Automotive Parts Manufacturer (Cooperation Since 2023)

Client Background:

A Tier 1 supplier to European automakers, facing strict requirements for high-temperature resistant materials.

Challenge:

Existing materials showed performance degradation under extreme conditions (180℃+), leading to a 12% end-customer complaint rate.

SUNLITE Solution:

Pre-sales phase: Expert team rapidly developed 3 customized solutions based on operating conditions and performance needs; selected a high-temperature resistant composite rubber formulation with lab tests showing a 40% improvement in temperature resistance.

Customization service: Optimized mold design using the 10,000+ case library, achieving 72-hour express prototyping — 60% faster than industry average.

After-sales support: Improved installation processes, increasing client production line yield from 89.

Outcomes:

Client repurchase rate increased to 100%, with 3 new product lines added.

Client testimonial: “Sunlite’s end-to-end service resolved a 2-year product issue in just 3 months.”

Client Case 2: US New Energy Equipment Company (Cooperation since 2024)

01

Client Background:

A global leading solar energy storage equipment manufacturer deploying high-reliability equipment in African deserts.

02

Challenge:

Equipment seals had a lifespan of only 6 months in dry, dusty environments—far below the design target of 3 years—leading to high maintenance costs.

03

SUNLITE Solution:

Need insight: Expert team collected on-site data (temperature, humidity, sand particle size) to develop a nano-coating sealing solution.

Technical empowerment: Optimized formulations via the national laboratory, extending weather resistance to 48 months while reducing material costs by 15%.

Full lifecycle service: Provided lifetime maintenance consultation and remote guidance for preventive maintenance, reducing unplanned downtime by 90%.

04

Outcomes:

Equipment failure rate in African markets dropped by 75%, saving $2 million in annual maintenance costs.

Client testimonial: “Sunlite’s service not only solved our problem but also helped us build a sustainable O&M system.”

V. Conclusion

Choosing Sunlite means gaining more than high-quality products—you gain an industry-leading service support system:

The only supplier offering a“full lifecycle service commitment”

Trusted by over 300 multinational enterprises

Innovate service models setting industry standards

Contact our service consultants today for your exclusive solution!

(WhatsApp ID: **********)